The mining industry is essential to moving to a greener economy

Mining is a complex industry that is often seen as unsustainable. Indeed, the industry faces many sustainability challenges, ranging from protecting the environment and reducing water use to maintaining good relationships with local communities and making sure end-of-life mines are handled well.

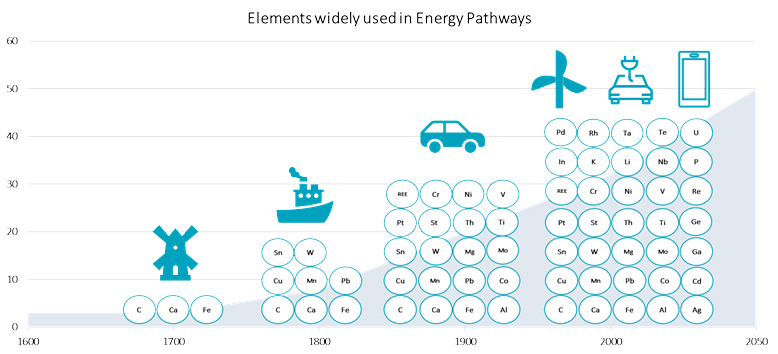

Yet, minerals (some of which we did not even know existed) are inextricably linked to the rise of mankind and civilisation. And our green future depends on it. As shown in the graph below, a variety of critical materials enable clean energy technologies such as photovoltaics, wind turbines, electric vehicles (EVs) and energy-efficient lighting. These clean energy technologies, in turn, reduce the greenhouse gas emissions that contribute to climate change.

EVs use four times more metals and minerals than conventional vehicles

The shift to electric vehicles will be an important driver of future demand for metals. Estimates of the metal requirements across the EV supply chain to achieve the target of 30% market share (amounting to 30 million EV sales by 2030) are an estimated additional:

- 4.1 million tonnes of copper (18% of 2017 supply),

- 1.1million tonnes of nickel (55% of 2017 supply), and

- 314,000 tonnes of cobalt (332% of 2017 supply).

Other less well-known rare earth elements (REEs) are also critical components in wind turbines and EVs. They use permanent magnets to convert energy, forming an integral

Materials critical to the energy industry. Source: Zepf V, Reller A, Rennie C, Ashfield M & Simmons J, BP (2014)

Part of the functionality of their lightweight, high-power generators and motors, one such rare earth compound used in this process is neodymium iron boron.

The total mass of REEs used depends on the application and the manufacturer; it could be several hundred kilograms for a wind turbine, whereas an electric drive vehicle may only need one kilogram of them. And their use is massively increasing: one study estimated that demand for dysprosium and neodymium could increase by 700% and 2,600%, respectively, over the next 25 years in a business-as-usual scenario.

Energy transition at the cost of marine life in our oceans?

This development has driven up the cost of many rare earth metals, which in turn improves the business case for seabed mining. Some seabed areas contain the world’s largest reserves of cobalt, nickel and other valuable minerals. The industry’s long-awaited regulations – in the form of a mining code – are due to be finalized this year. This would put into place a process whereby contractors can apply for 30-year licenses to mine assigned ‘claim areas’ in parts of the international seabed.

Scientists and conservationists, however, are worried that the creation of regulations will encourage the industry to start mining long before there is enough information on how operators can avoid causing serious environmental harm. The scarce data that exists suggests that deep-sea mining will have a devastating, and potentially irreversible, impact on marine life.

This is in clear contravention of Principle 15 of the Rio Declaration on Environment and Development, which states that a precautionary approach should be applied where there are threats of serious or irreversible damage. A lack of full scientific certainty shall not be used as a reason for postponing cost-effective measures to prevent environmental degradation. In addition, Sustainable Development Goal 14 (life below water) calls for the sustainable management and protection of marine and coastal ecosystems as one of its sub-targets.

Innovation, innovation, innovation

For some minerals, the industry continues to use essentially identical mineral processing technologies (the process of separating commercially valuable minerals from their ores) to those developed over 50 years ago, leaving significant room for improvement based on new science.

Mining has typically relied on building up scale as its main business model. Mining larger assets also leads to larger environmental footprints and more waste. However, the viability of new mineral deposits is increasingly limited due to low grades or other technical challenges, and their accessibility may be challenged by political unrest, social opposition and/or environmental barriers.

Innovation is therefore needed to help mitigate some of these concerns. The development of new separation technologies is considered to be one of the great challenges for the industry. New techniques can enhance mineral processing with the minimal consumption of chemicals, water and energy.

According to Deloitte, mining companies have started to show greater interest in leading-edge technologies, and while they aren’t rapidly adopting them, they are considering new ways of doing things. Exciting new technologies that could be genuine game-changers are, for example:

- The use of bacteria capable of extracting minerals in situ, and

- Bio-remediation processes that use natural enzymes to clean sites contaminated by metal leaching and drainage.

While still relatively new, genomics solutions have already been used to bio-remediate polluted soils, improve mine drainage and mitigate threats to biological diversity through bio-monitoring.

To address the challenges associated with critical materials, more effort will be needed to improve reuse and recycling in order to reduce the waste of critical metals, and lower the demand for newly extracted materials. The supply chain of clean energy technologies will also need to seek R&D opportunities to develop substitutes for some metals, like rare earth elements.

Investing in the transition

Mining companies are finding it difficult to redirect their strategic plans to facilitate the transition to a low-carbon economy. Staying invested in the infrastructure of existing mining assets is still preferred over new innovations that cater for the post-industrial age.

However, collaboration throughout the value chain, from suppliers to end customers, is needed. Moreover, teaming up with universities, industry bodies and research centers will be critical to enabling further innovation in the mining industry.

The financial industry can play a critical role in this process. Some of the bigger mining companies that are willing to move away from fossil fuels and make their operations more sustainable should be able to lower their cost of capital. Besides, they run less risk of being excluded by investors. We believe that if miners can get a better handle on the most material sustainability issues they face, they can become a crucial part of the solution.