The methane hunters.

Frackers in America’s largest oil field are letting massive amounts of natural gas spill into the atmosphere. Scientists and activists are trying to find the leaks and get them plugged before they cook the planet further.

By Zachary R. Mider

Five hundred miles above the Earth’s surface, the Copernicus Sentinel-5 Precursor, a satellite about the size of a pickup truck, has been circling the planet for four years, taking pictures of the atmosphere below. The satellite’s infrared sensor can see things humans can’t, and in 2019, Yuzhong Zhang, a postdoctoral fellow at Harvard, got a look at some of its first readings.

Zhang was interested in methane, an invisible, odorless gas. Although carbon dioxide from burning fossil fuels is the principal cause of global warming, methane has many times carbon’s warming power and is thought to be responsible for about a quarter of the increase in global temperatures caused by humans. When Zhang laid the satellite readings over a map of the U.S., the biggest concentration of the gas showed up as a red splotch over a 150-mile-wide swath of Texas and New Mexico.

The postdoc loaded the readings into a supercomputer to calculate what it would take to form that pattern. A few days later he had an answer. Beneath the splotch, Zhang discovered, 2.9 million metric tons of methane were pouring into the sky each year. By one measure, that cloud of gas is contributing as much to global warming as Florida—every power plant, motorboat, and minivan in the state.

Zhang, now at Westlake University in Hangzhou, China, calls it the “Permian methane anomaly.” The anomaly lies directly atop the Permian Basin, one of the most bountiful oil-producing regions in the world. Wells there churn out less-profitable natural gas alongside petroleum, and natural gas is mostly methane. Zhang’s research demonstrated that a surprising amount of that gas, more than twice what the U.S. government has estimated, is just spilling into the air unburned. Imagine that someone turned all the knobs on a stove without lighting a flame. Now imagine 400,000 stoves scattered across the Southwest, hissing day and night, cooking nothing but the planet itself.

Identifying and plugging these leaks could do more to slow climate change than almost any other single measure. Unlike carbon, methane breaks down relatively quickly in the atmosphere. That means efforts to curtail it can pay off within a generation. According to one recent estimate, almost one-third of the warming expected in the next few decades could be avoided by reducing human-caused methane emissions, without having to invent new technology or cut consumption. Some of that would come from cleaning up other sources, such as landfills and cattle feedlots. (Cow burps are full of methane.) But oil and gas fields are the most obvious places to start, because they offer the biggest potential reductions at the cheapest cost.

Only in the past few years has the urgency of the methane problem come into focus, partly because of new technology and scientific research that’s uncovering leaks from pipelines in Russia to old wells in West Virginia. The latest assessment, published on Aug. 9 by United Nations-backed scientists, says “strong, rapid, and sustained reductions” in these emissions are key to meeting climate goals. In the U.S., regulation hasn’t kept up. In many cases, energy producers and pipeline operators are free to spew methane into the air without running afoul of any law.

In lieu of regulation, nonprofit groups and activists are acting as self-appointed private eyes, running their own Permian monitoring programs and pressuring companies directly. Gas markets are responding, too. Last year a $7 billion contract to send Permian liquefied natural gas to France collapsed over concerns about the greenhouse gas footprint. Lenders and investors are also pushing for action. Now oil companies are launching their own drones, airplanes, and satellites in the service of mostly voluntary efforts to find the spills and stop them.

It’s unclear how far private and voluntary actions will go. One obstacle is the sheer size of the Permian, a sparsely populated scrubland where spills from open hatches, equipment malfunctions, and the like can continue for days before anyone notices. Another is the jumble of companies and wells. Even the Sentinel-5P’s powerful sensor has trouble identifying individual leaks. Spills are so large and numerous that, seen from space, they merge into one indistinguishable mass.

Up close, the Permian is flat and dry. Cows wander across lonely plains of mesquite, and rusting pump jacks dot the horizon. Wildcatters have been chasing oil here for a century, but nothing in the past compares to the frenzy that gripped the region about six years ago.

Advances in extraction techniques, including horizontal drilling and fracking, had opened up reserves in previously inaccessible shale rock, helping to drive down global energy prices. That set off a hunt for prospects that could be profitable even if oil stayed cheap, and the Permian’s unusual geology stood out. Meanwhile, Congress ended a longtime ban on oil exports, benefiting basins that produce light sweet crude, which foreign refineries are better-equipped to handle. Money poured in from oil majors and private equity funds. More than half the nation’s drill rigs were mobilized. Drilling rights neared $100,000 an acre, and hotels in Midland, Texas, the commercial hub of the oil patch, started charging Manhattan prices.

The landscape was transformed. Clusters of cylindrical oil tanks appeared everywhere, along with rectangular ponds as big as football fields holding the water needed for fracking. Camps for thousands of itinerant workers were laid out with military precision.

A few days after the ban was lifted, on Christmas Eve 2015, drillers broke ground on a new well whose story is a microcosm of the Permian. State Pacific 55-T2-8X17, as the site is known, sits on a stretch of rangeland near the Pecos River in Texas’ Loving County (population 169). Two months later, it was complete: a wellhead and six storage tanks squatting on a rectangle of bare earth.

The money behind State Pacific came from BHP Group, an Australian mining colossus that spent big to drill faster than rivals. State Pacific alone brought forth 166,000 barrels of oil and other hydrocarbon liquids in its first year, as well as 620 million cubic feet of gas.

As companies such as BHP started chasing Permian crude, there wasn’t much of a plan for the gas that came up with it. Gas is difficult to store, and getting it to market requires a complex system of pipelines, compressors, and cryogenic processing plants. In the most lucrative parts of the field, including Loving County, that infrastructure was inadequate or nonexistent. With gas fetching so little that the price sometimes went negative, companies could save money by just burning it off rather than waiting for pipelines to be built. Across the region, hundreds of flares began to light up the sky each night. From space, the desert looked as bright as Albuquerque.

Even when producers could hook up to a pipeline, these lines were often congested and prone to interruptions. At BHP wells such as State Pacific, the problems were compounded by frequent breakdowns of the diesel compressors required to push gas into pipelines at about 1,000 pounds per square inch. The machines tended to fail if the temperature or system pressure rose too high. Since the sites were unmanned, outages would stretch for days. According to readings from a U.S. satellite that can spot individual flares at night, BHP burned gas frequently at State Pacific during its first three years in operation, torching off at least one-fourth of the gas produced.

Theoretically, flaring shouldn’t contribute much to the methane problem, because burning methane converts it to carbon dioxide—still a greenhouse gas, but a far less potent one. Of course, that’s only true if the flare works as intended.

Long before Zhang tallied the scale of the damage in the Permian, Sharon Wilson, an activist from Dallas, was driving across Texas with a $100,000 camera, hunting for leaks. Wilson works for the environmental advocacy group Earthworks, and her hardware makes methane show up inky black in photos.

If a satellite offers a godlike view of the region, Wilson can track individual plumes right to the source. In May, during one of her regular trips to West Texas, she was in the back of a rented GMC Yukon as an Earthworks colleague steered down a highway past freshly plowed cotton fields. In her lap, the camera, a FLIR GF320, was whirring softly, the sound of a cooling mechanism that keeps its guts colder than dry ice.

“Your faucet drips, that’s a leak,” Wilson said, her graying blond hair tucked under a baseball cap. “I hardly ever see a leak out here. I see a garden hose. A fire hose. A volcano.”

After each trip, Wilson uploads the most dramatic pictures to YouTube and emails them to state regulators—methane clouds pouring from broken valves, malfunctioning engines, and open hatches—hoping to pressure companies and government officials to clean things up.

Wilson, 68, didn’t think much about the environment when she worked for an oil marketing company. That changed, she says, when she lived in the prairie country north of Fort Worth and saw fracking ruin the place. Now she calls company executives “gasholes” on Twitter and enjoys recounting stories of her run-ins with hostile oilfield workers, whom she always nicknames Jethro.

Some of the most common culprits Wilson has found are flare stacks. These are tall pipes crowned with burners designed to torch off unwanted gas. Wilson says they frequently malfunction—the flames go out, allowing a stream of invisible gas to jet into the air. To the naked eye, it’s impossible to tell anything’s amiss.

David Lyon had seen Wilson’s videos of misbehaving flare stacks, but he wasn’t sure what to make of them. Lyon, an Arkansas native, is the lead scientist for a massive Environmental Defense Fund research project in the Permian charting the pollution in unprecedented detail. Do flares really get snuffed out all that often, he wondered? He dispatched a contractor to fly over hundreds of randomly selected flare stacks in a helicopter to find out.

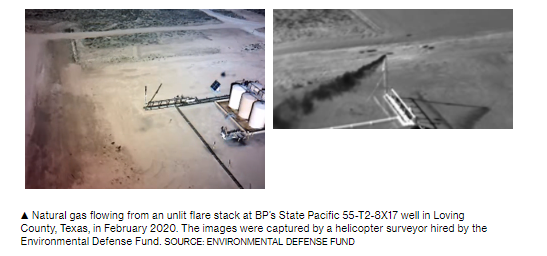

State Pacific was one of the first sites on the list. One sunny February day in 2020, the 20-foot-tall flare stack on the south end of the facility looked inert, with no flame visible. When the contractor pointed at it an infrared camera like the one Wilson uses, he saw a huge plume of black gas spewing from the stack and drifting off into the distance.

State Pacific wasn’t the only one. Lyon found that 5% of stacks with gas flowing through them were unlit, and an additional 6% were only partially burning. If those rates are typical of the entire Permian, Lyon estimates, that alone could explain the origin of 300,000 metric tons of methane a year. “I’ll admit I was skeptical,” he says. “But then we get out there and see, yeah, it actually is that bad.”

Lyon’s work is the latest chapter in EDF’s decade-long effort to unlock the secrets of methane. In 2011, Steven Hamburg, the group’s chief scientist, took note of how cheap, abundant shale gas was reshaping the country’s energy mix, overtaking coal as the workhorse of the electric power industry. Since burning gas produces about half the carbon dioxide of burning coal, carbon emissions in the U.S. were dropping for the first time in a generation. That seemed, at first glance, like a lucky break for the environment.

But Hamburg wondered how much of that progress was an illusion. Release a ton of methane today, and over the next two decades it will warm the planet as much as about 80 tons of carbon. Only a small fraction of natural gas would have to spill from wellheads, plants, and pipelines to make it worse for the planet than coal, especially in the short term. Hamburg quizzed industry and government experts: How much was leaking? He concluded that no one really knew and that official U.S. Environmental Protection Agency estimates were little more than guesses. So in 2012, EDF undertook the biggest research project in its history. If the government wouldn’t figure out how much methane is leaking, Hamburg reasoned, let’s do it for them.

Six years, $18 million, and several dozen peer-reviewed papers later, Hamburg had his answer: The U.S. oil and gas industry was losing about 13 million metric tons a year, or 2.3% of gas production—60% more than the EPA was estimating. (The EPA has acknowledged that studies such as EDF’s can reveal flaws in its estimates, but it hasn’t yet adopted the group’s numbers.) That rate erases most of natural gas’s climate advantage over coal, especially in the short term, and highlights the urgency of getting methane under control. The bigger the leak, the bigger the payoff for plugging it.

With Lyon’s Permian Methane Analysis Project, EDF is moving beyond just counting molecules. The goal is to reveal whose equipment is leaking, and how much, and publish the findings to compel companies and regulators to take action. University researchers and contractors do the fieldwork, with sensor-laden vans and airplanes carrying methane detectors and stationary monitors mounted on mobile-phone towers. Think of the project as a thousand Sharon Wilsons, armed with the scientific method and more money.

Lyon found his biggest spill last September. An airplane working for EDF picked up a large concentration of methane near a gas compression station south of Midland and circled back for a look. It found a huge cloud of gas jetting from a tank. EDF later calculated the size of the release at 12 tons of methane per hour. That’s about the same climate impact you would create if you started up every car in the state of Maine and left them all idling.

The plant’s owner, Targa Resources Corp., declined to comment to Bloomberg Businessweek, but it told state officials in an email that a wiring problem had caused one of the plant’s compressors to shut down. Pressure built up to dangerous levels, triggering a safety valve to release the gas. The company called it “not a foreseeable or avoidable occurrence” and said such mishaps are not uncommon across the Permian because pipelines are frequently running at capacity.

Given the scale of the Permian, the thousands of wells, tanks, flares, hatches, separators, compressors, and plants in use, unforeseeable and unavoidable things are happening all the time. “Things won’t work like they’re supposed to work on paper,” Lyon says. “It takes sometimes a while for people to realize that. There may even be disincentives for them to work. If they get bonuses based on how much oil they pump, then yeah, they’re incentivized to go as fast as possible and not worry about emissions.”

The contractor who found Lyon’s unlit flares is a 66-year-old former oilman named David Furry. Years ago, he pioneered the use of infrared cameras to find gas leaks, and he runs a small detection business catering mostly to oil and gas companies. Furry doesn’t consider himself an environmentalist, but he’s realistic about the scale of the pollution he’s documented. He estimates that about 1 in 5 sites he checks has some kind of emission.

One afternoon in May, in his office behind a shuttered gun shop in Early, Texas, Furry tucked a wad of Copenhagen Long Cut tobacco behind his lip and reflected on the future of the Permian. He’d recently gotten a call from a gas exporter wondering how much it would cost to check suppliers’ wells for leaks. That way the exporter could market “low-emissions” gas, akin to a fair-trade label on coffee.

“I was raised out there,” Furry said. “And you know, in the old days, when you had an oil spill, you’d throw a little dirt over it. Cover it up. Nowadays, things are different. But the thing about emissions is people can’t see ’em. They’re not thinking about emissions.” Furry tapped a finger to his temple. “The industry as a whole is going to have to be retrained to think emissions. And some are already starting. But not all.”

BP Plc, the former British Petroleum, has long positioned itself as more climate-conscious than its rivals, and it’s been at pains to improve its image in the U.S. since it caused a gargantuan oil spill in the Gulf of Mexico in 2010. BP acquired BHP’s assets in the Permian in 2018. When it assumed control the following year, the wells were flaring about 16% of the gas they produced, one of the highest rates in the basin. “We asked ourselves one question,” said David Lawler, the head of BP’s U.S. operations, in a blog post in April. “How can we do this differently?”

Some changes came right away. BP began disclosing its flaring activity at State Pacific to the state and sought permits to flare there and at dozens of other wells—steps that BHP, like many operators in Texas, hadn’t bothered with. BHP said in a statement that it strove to limit flaring and emissions in the Permian and that it “sought appropriate permits.”

At the same time, BP began re-plumbing the operation to eliminate the need to flare. Rather than rely on those touchy machines at each well site, it started building centralized compression stations with more reliable electric motors. BP estimates that the project will cost more than $1 billion and will eventually pay for itself through the sale of gas that would otherwise be wasted. The effort has already reduced its flaring in the basin to less than 2% of production. In his blog post, Lawler said BP would end routine flaring at onshore U.S. operations completely by 2025.

Last October the company began installing devices across its Permian facilities that alert off-site employees if a flare isn’t working properly, according to Megan Baldino, a spokesperson. Such a device went in at State Pacific late last year.

While BP’s efforts in the Permian may be the most high-profile, almost every company of any size is announcing a plan to lower emissions and cut flaring. Some have renounced the practice of bringing wells online before a gas-gathering pipeline is in place and are rolling out costly monitoring programs. After testing eight technologies, Exxon Mobil Corp. said this year that it’s hiring a company that shoots lasers from an airplane to spot methane leaks.

In another era, oil producers could have safely ignored environmental critics such as Wilson and Lyon. But just a few months after the French gas deal was canceled, something even more shocking hit executive boardrooms: Exxon’s shareholders voted to replace three board members, handing a victory to critics who said the company wasn’t doing enough to prepare for a low-carbon future. Lyon talks frequently to Wall Street investors. They always ask the same question these days, he says: Who has their emissions under control, and who doesn’t?

Lyon’s answer is usually some version of “it depends.” He says the mess in the Permian can’t be blamed on a few bad actors, and for all the money EDF has spent there, it still doesn’t have a comprehensive picture. But one is coming into focus. A few weeks ago, Lyon dispatched an airplane with even fancier gear, a NASA-designed instrument that can snap pictures of methane plumes over a broad swath of the region with enough precision to identify the source. In 2022, EDF will launch its own $88 million satellite, capable of peering into oil fields around the world with hundreds of times the resolution of the Sentinel-5P.

Regulation is starting to catch up, though unevenly. While Texas hasn’t taken significant action on either flaring or methane, the New Mexico Environment Department, after consultation with EDF, is phasing in limits on both. A federal methane rule, which applied to a limited number of oil facilities, was restored this year after being gutted by the Trump administration. Now the EPA is crafting a rule that would apply to more wells.

Wilson has heard the companies’ promises, and she doesn’t buy them. She met Lyon once, at a congressional hearing in New Mexico in 2019 after he testified about how oil producers could tackle methane with frequent inspections and better equipment. “Incremental changes and all that,” she says. “I was like, ‘David, David. That shit doesn’t work. It does not work.’ ”

Oil companies have been promising to clean up their act for decades, she says, and in that time they just drilled more and polluted more. The only way to clean up the Permian, she says, is to stop drilling. “As long as oil and gas keeps expanding, methane and CO2 is going to go higher.”

Even taking the company pledges at face value, it’s hard to know how long they’ll last. Right now, producers are retrenching after years of frenzied drilling ended in a Covid-fueled slump. In this go-slow environment, it’s not so much of a sacrifice to try to end flaring or cut emissions. The question is what the industry will do when the next boom gets going, in the Permian or somewhere else, and there’s money to be made by moving fast. And while Wall Street is forcing large, publicly traded companies to take action on emissions, many private operators are still doing whatever they please. Some of the majors have found themselves in the curious position of calling for more aggressive regulation so their voluntary pledges don’t put them at a disadvantage.

In May, Lyon’s team published the latest findings from that network of sensors installed on mobile-phone towers throughout the basin. Methane emissions plunged in April 2020 as the pandemic put the world economy on ice. But by the end of last summer, levels were already as high as they were when the year began. The stoves in the desert had switched back on.

20 August 2021

Bloomberg Green